Overview of Aluminum Foil Coated Aerogel Blanket for Industry Insulation

Aluminum Foil Coated Aerogel Blanket for Industry Insulation integrates the world’s best insulation properties into a thin, protective layer. This advanced material transforms surfaces with minimal thickness, enabling high thermal resistance for demanding industrial, construction, and aerospace applications where space and weight are critical.

Features of Aluminum Foil Coated Aerogel Blanket for Industry Insulation

-

Superior Thermal Performance: Provides exceptional insulation with minimal application thickness.

-

Rerevaka na wai & Protective: Repels water and offers resistance against corrosion and weathering.

-

Flexible & Conformable: Seamlessly adheres to complex geometries and substrates.

-

Lightweight & Space-Efficient: Dramatically reduces insulation bulk without compromising efficiency.

-

Durable & Long-Lasting: Maintains performance integrity under mechanical stress and temperature extremes.

(Aluminum Foil Coated Aerogel Blanket for Industry Insulation)

Specification of Aluminum Foil Coated Aerogel Blanket for Industry Insulation

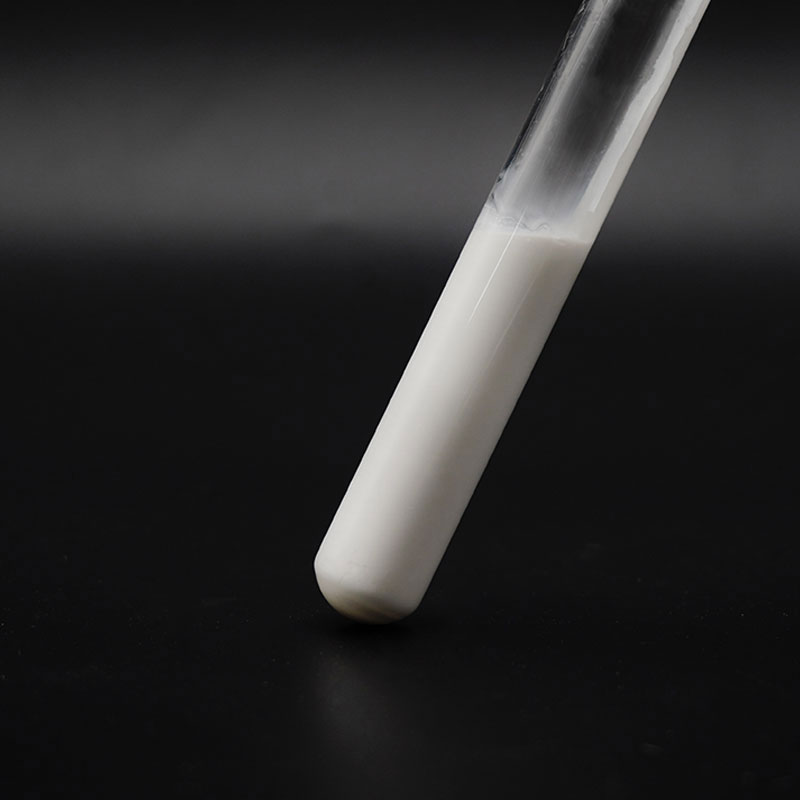

Aluminum foil covered aerogel covering is a high-performance insulation product produced commercial usage. It integrates the ultra-low thermal conductivity of aerogel with the reflective residential properties of light weight aluminum foil. This product uses superb heat resistance and energy-saving efficiency popular settings. The core of the blanket is silica aerogel, which has one of the most affordable thermal conductivities among solid materials. The outer layer is a long lasting light weight aluminum foil that mirrors radiant heat and secures versus wetness and mechanical damages.

This insulation covering functions well in temperatures varying from minus 200 levels Celsius to plus 650 levels Celsius. It remains secure under extreme conditions and does not deteriorate easily. The material is light-weight and flexible, making it simple to cut, shape, and set up around pipelines, tanks, and complicated tools. Its thin account saves area contrasted to typical insulation like mineral wool or fiberglass.

The aluminum foil surface also serves as a vapor obstacle. This aids stop condensation and rust under insulation, which is a common problem in industrial setups. The blanket resists water absorption and keeps its shielding value also in damp or wet problems. It is non-combustible and fulfills fire security standards, adding an added layer of security.

Industries such as oil and gas, petrochemicals, power generation, and aerospace use this product to improve thermal performance and reduce power loss. It is particularly valuable where space is restricted or where high efficiency is needed in rough settings. The item can be found in common roll sizes however can be customized for specific job requirements. Handling and setup require standard security equipment, as the material may create fine dirt throughout reducing. On the whole, aluminum foil coated aerogel covering supplies trustworthy, lasting insulation with minimal maintenance.

(Aluminum Foil Coated Aerogel Blanket for Industry Insulation)

Applications of Aluminum Foil Coated Aerogel Blanket for Industry Insulation

Light weight aluminum foil coated aerogel blanket is a leading option for commercial insulation. It integrates the lightness of aerogel with the reflectivity of aluminum foil. This mix offers solid thermal resistance in a slim, flexible type. Factories use it to cut heat loss and conserve power.

The covering functions well in high-temperature settings. It deals with warm up to 650 ° C without damaging down. That makes it excellent for pipelines, boilers, and exhaust systems. It additionally withstands water and moisture. So it remains reliable also in wet or humid locations.

Its thin account conserves area. Standard insulation usually requires thick layers. This covering supplies the exact same performance in much less space. That assists in tight areas where room matters. Installment is basic also. Employees can cut it with fundamental tools and fit it around complex shapes.

Industries like oil and gas, power generation, and chemical handling rely upon this material. It keeps tools running securely and efficiently. The aluminum layer reflects convected heat. The aerogel core obstructs conductive and convective warm circulation. Together, they reduce surface temperatures and protect employees.

This insulation additionally reduces operating costs. Much less warmth loss means much less gas is required. That lowers emissions and sustains sustainability goals. Maintenance remains reduced because the material does not deteriorate rapidly. It holds up under vibration, pressure, and duplicated thermal biking.

Safety and security improves too. The covering is non-toxic and non-combustible. It fulfills fire safety criteria made use of in numerous countries. Plants can use it without fretting about added risks. Its resilience indicates fewer substitutes and less downtime.

On the whole, aluminum foil layered aerogel covering supplies clever, long-lasting insulation for tough industrial jobs.

iTukutuku ni Kabani

Graphne Aerogels e dua na dausoli iyaya ni kemikali nuitaki ni vuravura raraba & dauteitei kei na sivia na 12-yabaki-vakatovotovo ena kena vakarautaki na super cecere-na ivakarau ni aerogel kei na graphene ivoli.

Na kabani e tiko kina e dua na tabana ni tekinolaji vakacakacaka kei na Tabana ni Veiqaravi ni Quality ., e dua na vale ni vakadidike vakarautaki vinaka ., ka vakaiyaragitaki ena iyaya ni veivakatovolei torocake kei na vanua ni veiqaravi ni kasitama ni oti na volivolitaki ..

Kevaka o vakasaqara tiko na graphene cecere ., aerogel kei na veika e buli, yalovinaka vakila na galala mo veitaratara kei keda se kiliki ena veika e gadrevi me vakau e dua na vakatataro ..

Na iwalewale ni sausaumi

L/C, T/T, Iunioni ni Tokalau, Pepa, Kadi ni dinau kei na so tale.

Vakauta

E rawa ni vakau ena wasawasa ., ena cagi, se ena kena vakaraitaki ASAP ena gauna ga e ciqomi kina na sausaumi.

5 FAQs of Aluminum Foil Coated Aerogel Blanket for Industry Insulation

What is an aluminum foil coated aerogel blanket?

It is a flexible insulation material made of silica aerogel and covered with aluminum foil. The aerogel provides very low thermal conductivity. The foil layer adds strength and reflects heat.

Why is it used in industrial insulation?

Industries need materials that stop heat loss or gain effectively. This blanket works well at high and low temperatures. It saves energy and keeps equipment running safely.

How does it compare to traditional insulation?

Traditional options like fiberglass or mineral wool are thicker and heavier. The aerogel blanket is thinner but gives better insulation. It also resists water and does not absorb moisture easily.

Is it safe to handle?

Yes, it is safe when used as directed. The blanket does not contain harmful fibers. Workers should still wear gloves and eye protection during installation to avoid skin or eye irritation from small particles.

Can it be used outdoors?

Yes, the aluminum foil coating protects the aerogel from weather. It resists UV light, rain, and humidity. This makes it suitable for outdoor pipes, tanks, or ducts without extra covering.

(Aluminum Foil Coated Aerogel Blanket for Industry Insulation)