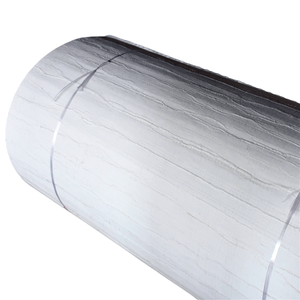

Overview of Customized Single-Sided Aluminum Foil Aerogel Insulation Blanket

Aerogels are ultralight, highly porous materials known for their exceptional insulation properties, remarkable low density, and incredible strength-to-weight ratios. Often referred to as “frozen smoke” due to their ethereal appearance, aerogels are produced by replacing the liquid component of a gel with gas, typically through supercritical drying, which avoids collapse of the gel structure. Composed primarily of air (up to 99.98%), these materials exhibit a wide array of unique characteristics that make them valuable across various industries.

Features of Customized Single-Sided Aluminum Foil Aerogel Insulation Blanket

-

Extremely Low Density: Aerogels are some of the world’s lightest solids, with densities as low as 0.001 grams per cubic centimeter.

-

Superb Insulation: They possess extremely low thermal conductivity, making them among the best insulators known to man, effective at temperatures from -270°C to 1,000°C.

-

High Porosity: With a porous structure that can reach up to 99.9%, aerogels have an incredibly large internal surface area, enhancing their functionality in absorption and catalysis applications.

-

Translucent to Transparent: Depending on their composition, aerogels can transmit light, giving them a unique semi-transparent or transparent appearance.

-

Mechanical Strength: Despite their fragile appearance, aerogels can be engineered to possess significant mechanical strength, capable of bearing considerable weight.

-

Chemically Inert: Many aerogels are chemically stable and resistant to corrosion, making them suitable for harsh environments.

(Customized Single-Sided Aluminum Foil Aerogel Insulation Blanket)

Parameters of High-Strength Copper Steel Composite Plate Made in China for Explosion Bonding & Transition Joints

High-strength copper steel composite plate made in China is developed for surge bonding and shift joints. This product incorporates the toughness of steel with the conductivity and deterioration resistance of copper. The bonding procedure makes use of controlled explosions to fuse the two steels with each other. This creates a strong, dependable joint that holds up under high tension and severe conditions.

The steel layer supplies architectural assistance and longevity. The copper layer supplies exceptional electric and thermal conductivity. With each other, they develop a composite that functions well popular industrial applications. Typical usages consist of power transmission tools, shipbuilding, chemical handling plants, and warm exchangers.

Common thickness arrays from 4 mm to 50 mm. The copper side normally measures in between 1 mm and 10 mm thick. The steel base can be carbon steel, low-alloy steel, or stainless-steel, relying on the need. The copper utilized meets conventional purity degrees, typically above 99.9%.

Bond toughness is a crucial criterion. It typically surpasses 200 MPa, making sure the layers stay securely attached throughout procedure. Shear toughness and tensile toughness are also examined to confirm efficiency. The user interface in between copper and steel reveals no voids or weak points when inspected with ultrasound or other non-destructive methods.

Surface area high quality matters as well. Both sides are cleaned up and smoothed to fulfill sector criteria. Sides are cut uniformly. Plates can be cut, bent, or machined without harming the bond. Customized sizes and shapes are readily available based on project requirements.

Suppliers in China comply with rigorous quality assurance steps. Each set goes through chemical evaluation, mechanical testing, and aesthetic checks. Accreditations like ISO 9001 and material examination reports are offered with every order. This guarantees users get a regular, reliable item whenever.

(Customized Single-Sided Aluminum Foil Aerogel Insulation Blanket)

Applications of High-Strength Copper Steel Composite Plate Made in China for Explosion Bonding & Transition Joints

High-strength copper steel composite plate made in China is widely made use of where strong, trusted bonding between copper and steel is required. This product integrates the high thermal and electrical conductivity of copper with the stamina and durability of steel. It is produced making use of explosion bonding, an approach that signs up with the two metals strongly without thawing them.

One significant usage is in power generation tools. Warm exchangers, condensers, and central heating boiler components commonly require this composite plate due to the fact that it manages warmth well and withstands deterioration. In shipbuilding, it appears in aquatic condensers and piping systems that must operate in salty, rough settings. The copper side battles corrosion from salt water while the steel side gives structural assistance.

The petrochemical market also counts on this product. Activators, distillation columns, and tank use copper steel change joints to attach various metal components securely. These joints prevent galvanic corrosion and minimize stress and anxiety at connection points. That helps prolong equipment life and decreases upkeep expenses.

Electric grounding systems benefit too. Copper performs electrical energy better than steel, yet steel is stronger. By utilizing the composite plate, designers get both advantages unharmed. It makes certain steady grounding while holding up under mechanical tons.

China’s manufacturing of this composite plate meets worldwide standards. Producers regulate top quality securely throughout surge bonding to prevent flaws like fractures or weak bonds. The outcome is a reliable product that performs well popular applications.

Due to the fact that it fixes the trouble of joining different steels efficiently, this composite plate has ended up being essential in numerous hefty industries. Its performance in high-temperature, high-pressure, or corrosive settings makes it a wise choice for designers looking for long-lasting reliability.

Applications of Customized Single-Sided Aluminum Foil Aerogel Insulation Blanket

-

Thermal Insulation: Used in aerospace for spacecraft insulation, and in commercial and residential buildings for energy-efficient windows and insulation materials.

-

Environmental Remediation: Aerogels’ high surface area makes them effective in absorbing pollutants like oil spills and heavy metals from water.

-

Sound Absorption: Their porous structure absorbs sound waves effectively, making them useful in noise reduction applications.

-

Electronics: Aerogels’ low thermal conductivity and electrical insulation properties find applications in semiconductor and battery technology.

-

Optics and Photonics: Translucent aerogels are used in optical devices, light-guiding structures, and as filters.

-

Drug Delivery: The high surface area can be utilized for controlled drug release, making aerogels candidates for advanced medical applications.

Company Profile

Graphne Aerogels is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality aerogel and graphene products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality graphene, aerogel and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

FAQs of Customized Single-Sided Aluminum Foil Aerogel Insulation Blanket

Q: Is Customized Single-Sided Aluminum Foil Aerogel Insulation Blanket fragile?

A: Traditional aerogels are brittle and fragile; however, advancements have led to the development of “flexible” or “rigid” aerogels that maintain their unique properties while being more durable.

Q: How is Customized Single-Sided Aluminum Foil Aerogel Insulation Blanket made?

A: Customized Single-Sided Aluminum Foil Aerogel Insulation Blanket is synthesized by replacing the liquid in a gel with gas without causing the structure to collapse. This is typically achieved through supercritical drying, where the solvent is converted to a supercritical state, allowing it to evaporate without forming liquid-gas interfaces that could damage the gel structure.

Q: Is Customized Single-Sided Aluminum Foil Aerogel Insulation Blanket expensive?

A: Historically, aerogels have been costly due to their complex manufacturing process. However, with technological advancements and economies of scale, costs are gradually decreasing.

Q: Can Customized Single-Sided Aluminum Foil Aerogel Insulation Blanket conduct electricity?

A: Most aerogels are poor conductors of electricity due to their porous, insulating nature. However, certain metal-oxide aerogels can display semiconducting or even conducting properties.

Q: Is Customized Single-Sided Aluminum Foil Aerogel Insulation Blanket environmentally friendly?

A: Aerogels themselves do not pose environmental hazards, and their use in insulation can reduce energy consumption. However, the production process may involve chemicals that require careful handling and disposal.

5 FAQs of High-Strength Copper Steel Composite Plate Made in China for Explosion Bonding & Transition Joints

What is a high-strength copper steel composite plate?

It is a metal plate made by bonding copper and steel together using explosion bonding. This method creates a strong joint between the two metals. The result keeps the good qualities of both materials—copper’s conductivity and steel’s strength.

Why use explosion bonding for this plate?

Explosion bonding uses controlled blasts to join copper and steel. This process makes a solid, clean bond without melting the metals. It avoids weak spots or impurities that other methods might cause.

Where are these plates used?

They are often used in industries like shipbuilding, power generation, and chemical processing. These fields need parts that handle heat well and resist corrosion. The copper side deals with electrical or thermal tasks, while the steel side gives structural support.

How strong is the bond between copper and steel?

The bond is very strong. Tests show it meets or exceeds international standards for shear strength and tensile strength. The joint stays stable even under high stress or temperature changes.

Are Chinese-made copper steel composite plates reliable?

Yes. Many Chinese manufacturers follow strict quality controls and international norms. They use advanced explosion bonding tech and test every batch. Buyers get consistent performance and good value.

(Customized Single-Sided Aluminum Foil Aerogel Insulation Blanket)