Overview of Thermal Insulation Aerogel Blanket/Panles/Particle/Granules/Powder/Coating/Paint/Composite Products

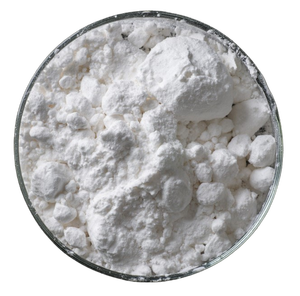

Aerogel powder is the granular form of the world’s lightest solid material, often called “frozen smoke.” This nanoporous substance is created by replacing the liquid in a gel with gas, resulting in an ultra-low-density solid with extraordinary properties. Our aerogel powder retains the exceptional qualities of monolithic aerogels in a versatile, easy-to-integrate format for diverse industrial and research applications.

Features of Thermal Insulation Aerogel Blanket/Panles/Particle/Granules/Powder/Coating/Paint/Composite Products

-

Extremely Low Thermal Conductivity: Offers superior insulation performance, even in extreme environments.

-

High Porosity & Surface Area: Features a nanoporous structure with a surface area exceeding 600 m²/g for exceptional adsorption and catalytic potential.

-

Ultra-Low Density: One of the lightest solid materials known to man.

-

Hydrophobic or Hydrophilic Options: Available in formulations that either repel or absorb water to suit specific application needs.

-

Excellent Fire Resistance: Inorganic silica-based powder is inherently non-flammable and can withstand high temperatures.

(Thermal Insulation Aerogel Blanket/Panles/Particle/Granules/Powder/Coating/Paint/Composite Products)

Specification of Thermal Insulation Aerogel Blanket/Panles/Particle/Granules/Powder/Coating/Paint/Composite Products

Thermal insulation aerogel products been available in numerous types including coverings, panels, fragments, granules, powder, finish, paint, and compounds. These products make use of aerogel’s ultra-low thermal conductivity to lower warm transfer. Aerogel coverings are adaptable and easy to install on pipelines, containers, or walls. They maintain their form under pressure and handle high temperatures well. Aerogel panels are inflexible and made use of where area is limited but strong insulation is needed. They work well in buildings, aerospace, and industrial setups.

Aerogel fragments and granules are little solid pieces that can fill up gaps or blend right into other materials. They include insulation without adding much weight. Aerogel powder is even finer and commonly used as an additive in plastics, rubbers, or building and construction blends. It aids improve thermal performance without changing the base product excessive.

Aerogel finishes and paints have aerogel particles suspended in a liquid base. You can comb, spray, or roll them onto surfaces like metal roofs, walls, or machinery. When dry, they create a thin layer that obstructs warm flow. These serve when you can not include thick insulation layers.

Aerogel compounds incorporate aerogel with fibers, foams, or other matrices. This produces materials that are both solid and shielding. They prevail in safety apparel, vehicle components, and specialized packaging.

All these items share crucial qualities: they are lightweight, withstand warmth well, and occupy less room than standard insulation. They likewise handle moisture better than lots of alternatives. Most kinds operate in temperatures from minus 200 ° C to over 650 ° C depending upon the solution. They do not burn easily and meet numerous fire safety criteria. Installation is simple and does not require unique tools most of the times. These functions make aerogel-based insulation a smart selection for energy effectiveness and area savings throughout many sectors.

(Thermal Insulation Aerogel Blanket/Panles/Particle/Granules/Powder/Coating/Paint/Composite Products)

Applications of Thermal Insulation Aerogel Blanket/Panles/Particle/Granules/Powder/Coating/Paint/Composite Products

Thermal insulation aerogel products come in lots of forms such as coverings, panels, fragments, granules, powder, coatings, paint, and composites. These materials are used throughout different markets since they supply strong warm resistance with very little weight or density. Aerogel blankets wrap around pipelines, storage tanks, and ducts in oil and gas centers to cut heat loss and save energy. They also protect employees from warm surface areas. In building and construction, aerogel panels fit into wall surfaces, roofs, and floors to improve structure effectiveness without occupying much space. This assists meet green building requirements.

Aerogel fragments and granules go into shielding fills up for home appliances like fridges or into specialized concrete blends. They reduced thermal conductivity while keeping the mix workable. Powdered aerogel is mixed into various other products to enhance their insulating power. It can be added to plastics or rubbers utilized in auto parts. Aerogel-based layers and paints use like regular paint but create a slim layer that blocks heat transfer. These are useful on steel roofs, tank, and even spacecraft exteriors.

Composite products combine aerogel with fibers or materials to create adaptable yet sturdy insulation sheets. These prevail in aerospace and aquatic applications where fire security and weight matter a lot. Safety clothes for firefighters often uses aerogel compounds to secure versus extreme warm. Industrial stoves and heaters also utilize these compounds to keep high internal temperatures with much less power.

All these aerogel layouts share the exact same core benefit: they catch air in a nanostructure that reduces warmth movement. This makes them far more efficient than conventional insulators like fiberglass or foam at the very same density. Their light weight and flexibility open usages where space, safety and security, or efficiency are tight restraints. Firms pick aerogel remedies when standard materials fall short on efficiency or style demands.

Company Profile

Graphne Aerogels is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality aerogel and graphene products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality graphene, aerogel and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Thermal Insulation Aerogel Blanket/Panles/Particle/Granules/Powder/Coating/Paint/Composite Products

What is aerogel insulation made of?

Aerogel insulation starts with a gel. The liquid in that gel gets replaced with air. This leaves a solid material that is very light and full of tiny pores. Most thermal insulation aerogels use silica as the base.

How does aerogel keep heat in or out?

Heat moves slowly through aerogel because of its structure. The tiny air pockets inside block heat transfer. This makes it hard for heat to pass through. So it works well in both hot and cold conditions.

Is aerogel safe to handle?

Most commercial aerogel products are safe when used as directed. They do not give off harmful fumes. Still, you should wear gloves and a mask when cutting or installing loose forms like granules or powder to avoid skin or lung irritation.

Can aerogel get wet?

Standard silica aerogel absorbs moisture. That can lower its insulating power. Some products come with a water-repellent coating. Others are built into waterproof composites. Always check if the type you buy resists water.

Where is aerogel insulation used?

People use aerogel blankets in buildings, pipelines, and appliances. Granules go into walls or roofs during construction. Coatings and paints add insulation to surfaces like tanks or roofs. Composites work in aerospace, shipping, and outdoor gear where space and weight matter.

(Thermal Insulation Aerogel Blanket/Panles/Particle/Granules/Powder/Coating/Paint/Composite Products)